Types of Circuit Breakers⁚ A Comprehensive Overview

This overview explores the diverse world of circuit breakers, crucial safety devices protecting electrical circuits. From magnetic and thermal types to molded-case, air, oil, and vacuum breakers, each design offers unique advantages and applications. Miniature circuit breakers (MCBs), including types A, B, C, and D, cater to various needs. Selecting the right breaker involves careful consideration of voltage, current, and specific application requirements, ensuring optimal safety and system performance.

Introduction to Circuit Breakers

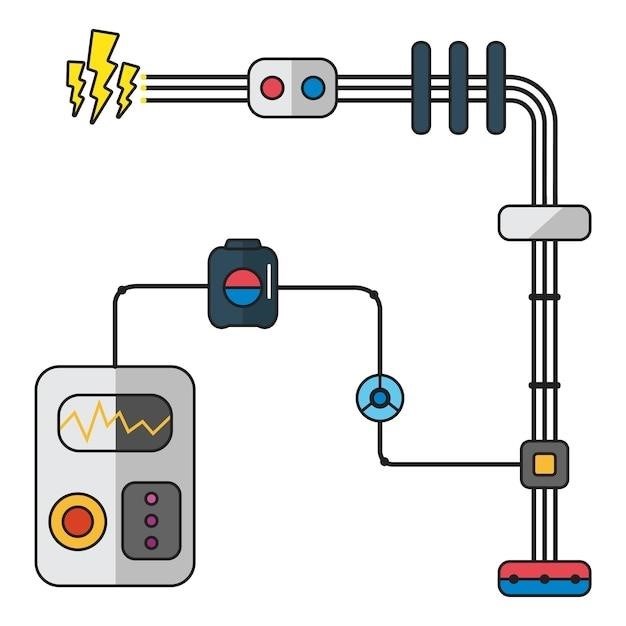

Circuit breakers stand as essential safety components within electrical systems, acting as automatic switches designed to protect circuits from damage caused by overcurrents or short circuits. Their primary function involves swiftly interrupting the flow of electricity when current levels exceed safe limits, thus preventing potential hazards such as fires or equipment malfunctions. This interruption mechanism safeguards both the electrical infrastructure and connected devices. Circuit breakers are activated either manually or automatically, providing a crucial layer of protection in various applications, ranging from residential settings to large-scale industrial installations. Their widespread use underlines their importance in ensuring the reliable and safe operation of electrical systems. The diverse types of circuit breakers reflect the varying needs and complexities of modern electrical networks, with each type possessing specific characteristics and applications.

Magnetic Circuit Breakers⁚ Principles and Applications

Magnetic circuit breakers leverage the principles of electromagnetism for their operation. An electromagnetic coil is incorporated into the breaker’s design; when excessive current flows through the circuit, it generates a powerful magnetic field within the coil. This amplified magnetic field exerts a force on a movable component within the breaker, causing it to physically separate the contacts and interrupt the current flow. The speed of this magnetic tripping mechanism makes magnetic circuit breakers particularly effective in protecting against short circuits, where rapid current surges pose a significant risk of damage or fire. Their applications span various sectors, including industrial settings requiring robust protection against high fault currents and residential applications where simpler protection from overloads is sufficient. The simplicity and effectiveness of this mechanism contribute to the widespread use of magnetic circuit breakers in numerous electrical systems.

Thermal Circuit Breakers⁚ Operation and Characteristics

Thermal circuit breakers utilize the principle of heat generation to detect and respond to overcurrents. A bimetallic strip, composed of two metals with different thermal expansion coefficients, forms the core of the mechanism. When an excessive current passes through the circuit, the bimetallic strip heats up. Due to the differing expansion rates of the two metals, the strip bends, eventually triggering a mechanical switch that interrupts the circuit. This process is relatively slow compared to magnetic tripping, making thermal breakers more suitable for protection against prolonged overloads rather than instantaneous short circuits. A key characteristic of thermal breakers is their inherent time delay; the tripping time is directly proportional to the magnitude of the overcurrent. This delayed response prevents nuisance tripping caused by brief current surges, such as those experienced when starting high-inrush motors. Their simple construction, reliance on readily available materials, and relatively low cost contribute to their prevalence in a variety of low-voltage applications.

Molded Case Circuit Breakers (MCCBs)⁚ Common Features and Uses

Molded case circuit breakers (MCCBs) represent a widely used type of electrical protection device, combining the functionality of a circuit breaker within a robust, self-contained molded casing. These breakers are characterized by their compact design, ease of installation, and relatively high interrupting capacity. Unlike their miniature counterparts, MCCBs are capable of handling significantly higher currents, ranging from tens to thousands of amperes, making them suitable for a broader range of applications. They commonly incorporate both thermal and magnetic tripping mechanisms, providing protection against both overloads and short circuits. The thermal element responds to sustained overcurrents, while the magnetic element provides rapid tripping for fault currents exceeding a predetermined threshold. MCCBs find extensive use in industrial and commercial settings, protecting various loads, from lighting circuits and motors to larger industrial equipment. Their versatility and robust construction make them a staple in electrical distribution systems, offering reliable and efficient overcurrent protection.

Air Circuit Breakers⁚ Design and Functionality

Air circuit breakers (ACBs) utilize air as the primary arc-quenching medium, offering a robust and reliable solution for interrupting high-voltage circuits. Their design typically involves fixed and moving contacts housed within an insulated enclosure filled with air. When a fault occurs, the breaker’s mechanism rapidly separates the contacts, creating an arc. The surrounding air, often assisted by various arc-quenching techniques, such as magnetic blowouts or arc chutes, helps to extinguish the arc, safely interrupting the current flow. ACBs are commonly used in medium-voltage switchgear found in industrial settings, substations, and power distribution systems. Their ability to handle high fault currents and interrupt large amounts of energy makes them essential components in ensuring the safety and reliability of electrical power systems. The specific design of an ACB can vary depending on voltage rating and interrupting capacity. They are known for their relatively simple construction, ease of maintenance, and ability to operate in various environmental conditions, contributing to their widespread adoption in various high-voltage applications.

Oil Circuit Breakers⁚ Historical Significance and Types

Oil circuit breakers (OCBs) hold a significant place in the history of electrical power systems, representing an early and effective method for interrupting high-voltage circuits. These breakers utilize oil as both an insulating and arc-quenching medium. When the contacts separate during a fault, an arc is formed, and the oil’s dielectric properties prevent flashover. Simultaneously, the intense heat of the arc decomposes the oil, producing gas bubbles that expand rapidly, further extinguishing the arc. OCBs were widely used for decades, particularly in high-voltage applications, due to their relatively high interrupting capacity and reliable operation. However, concerns regarding fire hazards associated with oil and environmental regulations led to their gradual replacement by other technologies, such as air and vacuum circuit breakers. Two main types of OCBs existed⁚ bulk oil circuit breakers, where the contacts are immersed in a large volume of oil, and minimum oil circuit breakers, which use a smaller quantity of oil. While largely superseded, OCBs remain a notable chapter in the evolution of circuit breaker technology.

Vacuum Circuit Breakers⁚ Advantages and Applications

Vacuum circuit breakers (VCBs) represent a significant advancement in switching technology, offering numerous advantages over their predecessors. The core of a VCB is a pair of contacts sealed within a vacuum-filled enclosure. This vacuum environment eliminates the need for insulating and arc-quenching media like oil or air, significantly reducing maintenance needs and fire hazards. The vacuum’s exceptional dielectric strength allows for compact designs, and the rapid arc extinction in a vacuum results in minimal arcing time and reduced wear on the contacts. VCBs are highly reliable and boast a long operational lifespan, making them cost-effective in the long run. Their applications range from low-voltage distribution systems to high-voltage transmission lines, often found in substations and industrial settings. The superior performance characteristics and environmental friendliness of VCBs have made them a preferred choice in many modern electrical systems, pushing aside older technologies.

Miniature Circuit Breakers (MCBs)⁚ Types and Selection Criteria

Miniature Circuit Breakers (MCBs) are compact, electromechanical switches designed to protect electrical circuits from overcurrent and short circuits. They are widely used in residential, commercial, and industrial settings. MCBs come in various types, primarily differentiated by their tripping characteristics. Thermal-magnetic MCBs combine thermal and magnetic mechanisms for broader protection against overloads and short circuits. Electronic MCBs utilize sophisticated electronics for more precise current sensing and tripping, often offering advanced features like time-delay tripping. Selection of an MCB depends on several critical factors including the rated current of the circuit, the type of load (resistive, inductive, or capacitive), the available fault current, and the required tripping characteristics. Compliance with relevant safety standards and environmental considerations are also important aspects to consider when choosing the appropriate MCB for a given application. Proper selection ensures reliable protection and optimal circuit performance.

Types A, B, C, and D MCBs⁚ Differences and Applications

The classification of miniature circuit breakers (MCBs) into types A, B, C, and D is based on their tripping characteristics in response to varying levels of overcurrent. Type B MCBs offer the most sensitive response, tripping quickly at currents between 3 and 5 times their rated current. They are suitable for applications with predominantly resistive loads, where inrush currents are relatively low. Type C MCBs are designed for applications with moderate inrush currents, tripping at 5 to 10 times their rated current. Commonly found in lighting circuits and some motor applications, they provide a balance between sensitivity and tolerance to surges. Type D MCBs are the least sensitive, designed for high inrush current applications like large motors or transformers, tripping at 10 to 20 times their rated current. The selection of the appropriate MCB type is crucial for optimal protection, preventing nuisance tripping while ensuring safety during fault conditions. Understanding the load characteristics and potential surge currents is paramount in making this crucial decision.

Selecting the Right Circuit Breaker⁚ Key Factors to Consider

Choosing the appropriate circuit breaker necessitates a comprehensive evaluation of several critical factors. Firstly, the voltage rating must precisely match the circuit’s voltage; using an under-rated breaker is extremely dangerous. Secondly, the amperage rating should be carefully selected to handle the circuit’s maximum current without overheating. Overloading a circuit breaker can lead to fire hazards. The type of load (resistive, inductive, capacitive) significantly influences the choice of breaker, as inductive loads, for instance, generate higher inrush currents. The breaker’s interrupting capacity (IC) must exceed the available fault current to ensure safe interruption during short circuits. Environmental conditions, such as ambient temperature and humidity, may also impact breaker selection, potentially affecting performance and lifespan. Finally, the intended application, whether it involves motor protection, lighting circuits, or general-purpose use, should be considered, as this influences the optimal tripping characteristics and other features required for proper operation and safety.

Choosing the Appropriate Breaker for Your Needs

Selecting the correct circuit breaker is paramount for ensuring both safety and optimal performance within any electrical system. The wide variety of available circuit breakers, each with unique operating mechanisms and capabilities, necessitates careful consideration of several key factors. Matching the breaker’s voltage and amperage ratings to the specific circuit requirements is crucial to prevent overheating and potential hazards. Understanding the nature of the load (resistive, inductive, or capacitive) and the system’s fault current level are also essential aspects of appropriate breaker selection. Furthermore, environmental factors and the specific application of the circuit (e.g., motor protection, lighting) should guide the choice of breaker type. Ultimately, proper selection ensures the reliable and safe operation of the electrical system, protecting equipment and preventing potential damage or injuries. Consult relevant standards and guidelines for further assistance in making an informed decision.